Description

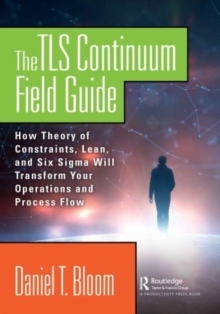

| Product ID: | 9780367139155 |

| Product Form: | Paperback / softback |

| Country of Manufacture: | GB |

| Title: | The TLS Continuum Field Guide |

| Subtitle: | How Theory of Constraints, Lean, and Six Sigma Will Transform Your Operations and Process Flow |

| Authors: | Author: Daniel Bloom |

| Page Count: | 242 |

| Subjects: | Production and quality control management, Production & quality control management, Engineering: general, Other manufacturing technologies, Environmental science, engineering and technology, Engineering: general, Other manufacturing technologies, Environmental science, engineering & technology |

| Description: | Select Guide Rating This book provides a roadmap for implementing a powerful technique will reduce waste and accelerate flow within a process -- The TLS Continuum methodology. This book provides a roadmap for implementing a powerful technique will reduce waste and accelerate flow within a process -- The TLS Continuum methodology. The letters TLS stand for the three components of the continuum. The letter T stands for the Theory of Constraints. Created by Dr. Eliyahu Goldratt in his book The Goal, it is a critically thinking-based system for determining where the obstacles lie within your organization. Through the use of various tools, it asks you to determine where the obstacles are in the process. The purpose of the Theory of Constraints (TOC) involvement in the continuum is to determine what needs to be changed, how to change it and how to accomplish the change. TOC operates at the level of the chain looking for the weakest link. It is in essence the hypothesis of the problem-solving method overall. The letter L stands for Lean. Most organizations are familiar with the concept of Lean. It is centered around removing waste from the organizational processes so that the customer receives their orders faster. Understand that faster may not mean cheaper or better quality, it means only that we expedite the process. The final letter is S and it represents the concepts of Six Sigma. The primary goal here is remove variation from the processes. If we combine the three letters of the acronym what we find that the TLS continuum is organized around a process in itself. We use the Theory of Constraints to locate and identify the obstacles within the system. What is holding up the process? Where is the weakest link in the process? With the introduction of TOC, the system asks you to elevate the obstacles and determine how to remove them. We use Lean to do what it is meant to do and that is to remove the obstacles. We have identified the obstacle and determined through the critical thinking tools how to remove that obstacle and then use the Lean tools to actually remove the waste. Finally, the system utilizes the Six Sigma tools to create the standard of work and remove any variation from the process. When we do this, we have completed the improvement process by creating a progressive system for resolving the problems that occur within many organizations. It is an evidence-based effort to identify, remove and improve the system so the problem does not recur. |

| Imprint Name: | CRC Press |

| Publisher Name: | Taylor & Francis Ltd |

| Country of Publication: | GB |

| Publishing Date: | 2024-02-28 |